Year after year, the news is filled with stories of workplace accidents that grab our attention, leaving behind a trail of injuries, loss of life, and extensive damage to valuable properties.

In today’s fast-paced industries, prioritizing a hazard-free workplace, adhering to safety regulations, and following safety standards have become imperative to safeguard employees and protect valuable assets.

However, certain industries face the unique challenge of handling flammable gasses, vapors, liquids, or combustible dust, which significantly escalates the risk of explosions and fires.

To mitigate these risks, the European Union introduced the ATEX rating, a certification that guarantees the safety of equipment and ensures the products designed for hazardous environments.

The prominence of ATEX rating has grown across various sectors such as oil and gas, chemicals, and manufacturing industries. This certification ensures that devices operate safely within zones characterized by varying levels of risk.

Understanding the categories, zones, and levels of protection associated with ATEX certification becomes vital when selecting suitable hazardous area equipment, machinery, and products for your workplace.

As a leading supplier of ATEX rated products, Intrinsically Safe Store is dedicated to ensuring workplace safety.

We deeply understand the importance of educating our clients about ATEX rating and its implications, which led us to create a comprehensive guide, ATEX rating 101, focusing on the fundamental aspects.

Our extensive range of ATEX certified products includes:

- Intrinsically safe cameras

- Explosion-proof fans

- Hazardous area portable safety lighting

- Intrinsically safe mobile devices

Each product undergoes rigorous testing to guarantee not to generate sparks or ignite fires in hazardous environments. By offering reliable solutions, we provide our customers with peace of mind and enhanced security.

Investing in ATEX rated intrinsically safe products is a strategic choice for businesses striving to establish a safe and secure workplace.

We are committed to delivering top-notch solutions that align with your safety goals, empowering your employees to work confidently, even in hazardous environments.

Our comprehensive ATEX rating 101 guide covers essential topics that enrich your understanding by helping you:

- Grasp the meaning and significance of ATEX rating

- Explore the categories and zones associated with ATEX rating

- Gain insights into ATEX regulations within the European Union

- Recognize the paramount importance of ATEX rating for ensuring safety

- Examples of ATEX rated products from Intrinsically Safe Store

By familiarizing yourself with ATEX rating, categories, and zones, you can establish a safer work environment, effectively preventing accidents and minimizing equipment damage.

Compliance with ATEX regulations in the European Union and adherence to safety standards is pivotal in implementing measures that mitigate potential hazards.

Join us on this informative journey as we embark on our ATEX rating 101 guide, providing you with the knowledge to ensure workplace safety.

What Is ATEX Rating?

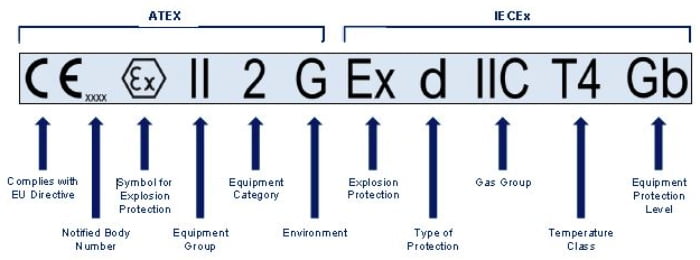

ATEX is the short form for the “ATmospheres EXplosibles Regulations.” It’s a European Union standard for intrinsically safe products installed in a hazardous-free workplace.

The ATEX rating is a technical standard developed to minimize the risk of explosions caused by electrical or non-electrical equipment, like safety cameras, safety fans, safety lighting, mobile devices, and others.

The ATEX rating helps companies to ensure that their safety equipment and other electrical or non-electrical tools are safe to use in hazardous environments. This rating provides guidelines for selecting and using equipment in potentially explosive atmospheres.

The categories and zones of ATEX rating explain the suitability of equipment for specific hazardous environments.

As described in the next section, they are essential for companies to manage the risks associated with explosions in their workspaces.

Expert Tip: The ATEX rating is crucial for selecting safe equipment in hazardous environments. Seek intrinsically safe products for a hazard-free workspace.

Categories of ATEX Rating

Intrinsically safe products play a crucial role in achieving a hazardous-free workplace, and the ATEX rating categorizes them for better understanding.

The ATEX directive defines two categories (1 and 2) for products suitable for use with flammable substances.

Category 1 is used for higher-risk situations that require rigorous safety measures, while Category 2 is used for lower-risk situations.

In Category 1 – Unleashing Unparalleled Protection

When it comes to Category 1 products, the emphasis is on providing an exceptional level of safeguarding, even in the face of adversity.

With the stringent requirement of guaranteeing protection in the event of two simultaneous faults, Category 1 products leave no room for compromise. They epitomize reliability and resilience, offering an unparalleled shield against potential hazards.

Category 2 – Embracing Standard Safeguards

While Category 1 sets the bar high, Category 2 products follow suit with their commitment to safety. These products possess robust protection measures that allow them to withstand a single fault.

They are designed to maintain their integrity and functionality even under adverse conditions, ensuring reliable safety for workers.

Although they may not offer the same level of fault tolerance as Category 1 products, Category 2 items still provide a solid defense against potential risks.

These categories apply to various safety equipment, including safety cameras, fans, lighting, and mobile devices.

Safety compliance and adherence to safety regulations are essential in any workplace environment.

Over time, safety regulations have evolved as safety and our understanding of hazards improved.

The ATEX rating is an excellent example of these developments. It provides a standardized approach to hazardous workplace protection.

Understanding ATEX rating is vital for ensuring safety compliance and meeting set safety standards and regulations.

Bonus Tip: To ensure full compliance with safety standards, choose ATEX-rated products that align with the hazard level of your workplace.

Zones of ATEX Rating

In hazardous work environments, one of the key features of ATEX rating is the division of the workplace into zones.

The ATEX directive identifies different zones depending on the level of risk and the frequency of occurrence of explosive atmospheres. This zoning system aims to ensure that only intrinsically safe equipment is installed in the hazardous area.

Let’s take a look at the zones.

Zone 0 – Constant Vigilance in Explosive Environments

Zone 0 represents an environment where an explosive atmosphere is present continuously or for extended durations.

It is a high-risk zone that demands utmost caution and stringent safety measures. Within this zone, the use of Intrinsically Safe products becomes crucial.

These specialized products are designed to prevent the release of sufficient electrical energy that could ignite any flammable in an explosive atmosphere.

By employing intrinsically safe equipment, the risk of ignition is mitigated, ensuring a safe working environment even in the face of continuous or prolonged exposure to explosive atmospheres.

Zone 1 – Navigating Potential Hazards With Care

Zone 1 is where an explosive atmosphere will likely occur under normal operating conditions.

Within this zone, the selection and installation of electrical equipment require meticulous attention to detail.

Equipment installed in Zone 1 must comply with ATEX categories and adhere to specific temperature, gas groups, and ignition temperature requirements.

These regulations ensure that the electrical equipment deployed in this zone is suitably designed and protected to prevent the ignition of potentially explosive atmospheres.

By meeting these stringent standards, businesses can effectively mitigate the risks associated with Zone 1 and maintain a safe working environment for their personnel.

Learn More: What does explosion proof mean?

Zone 2 – Vigilance in the Face of Abnormal Conditions

Zone 2 pertains to areas where an explosive atmosphere is only likely to occur under abnormal conditions or for short durations.

While the risk in Zone 2 is relatively lower than in Zone 0 or Zone 1, safety precautions remain paramount.

Electrical equipment suitable for use in Zone 1, which complies with ATEX categories and safety requirements, can be installed within this zone. This ensures that the equipment is designed to withstand abnormal conditions and provide an added layer of protection.

By adopting Zone 1-compliant equipment, businesses can effectively address the potential risks that may arise during abnormal situations or brief periods of explosive atmospheres in Zone 2, enhancing overall workplace safety.

One advantage of choosing Intrinsically Safe Store is that we offer custom designs tailored to your specific needs. We understand that every workplace has unique requirements regarding safety equipment and compliance with ATEX regulations.

By working with us, you can benefit from our expertise in developing customized solutions that align with your specific industry, environment, and safety goals.

Whether it’s designing specialized safety cameras, fans, lighting systems, or mobile devices, our team is dedicated to providing you with innovative and tailored products that enhance workplace safety.

With our custom designs, you can have peace of mind knowing that your safety equipment is optimized for your specific working conditions, further ensuring the well-being of your employees and the protection of your assets.

Want a quick summary instead? The following table provides a concise overview of the different ATEX zones, including the frequency at which explosive atmospheres occur and the specific safety measures required in each zone.

| Zone | Frequency Of Explosive Atmosphere | Safety Measures Required |

| Zone 0 | Continuously or for long periods | Use of Intrinsically Safe products, strict safety measures |

| Zone 1 | Likely under normal operating conditions | Meticulous selection and installation of compliant electrical equipment |

| Zone 2 | Likely only under abnormal conditions or for short durations | Adoption of Zone 1-compliant electrical equipment, heightened safety precautions |

ATEX Regulation in the EU

The ATEX regulation in the EU is a comprehensive set of safety regulations designed to ensure a hazardous-free workplace.

It mandates that all intrinsically safe products must adhere to specific safety standards to minimize the risk of potentially harmful explosions.

These regulations apply to all industries where potentially explosive materials are present, from petrochemicals to pharmaceuticals.

The table below provides a summary of various industries that are affected by ATEX regulations, the potentially explosive materials found within them, and the typical ATEX zones for their work areas.

| Industry | Potentially Explosive Materials Commonly Found | Required ATEX Zone For Typical Work Areas |

| Petrochemicals | Flammable gases, vapors, or mist | Zone 0, Zone 1, Zone 2 |

| Pharmaceuticals | Dusts, chemicals | Zone 20, Zone 21, Zone 22 |

| Agriculture | Grain dust, organic dust | Zone 20, Zone 21, Zone 22 |

| Mining | Methane, coal dust | Zone 0, Zone 1, Zone 2 |

| Food Processing | Flour dust, sugar dust | Zone 20, Zone 21, Zone 22 |

ATEX rating compliance is crucial for companies to meet safety regulations and avoid legal penalties.

All safety equipment must meet specific ATEX categories and zones outlined in the previous sections.

Employers must also maintain continuous safety compliance by regularly conducting audits and risk assessments to meet safety standards.

Adhering to ATEX regulations isn’t just a legal obligation; it’s essential for ensuring a safe working environment for all employees.

By implementing safety measures and equipment that comply with ATEX rating standards, companies can minimize the risk of potential explosions and injuries, promoting a safe and productive workplace.

Safety Tip: Adhering to ATEX regulations promotes a safe working environment by minimizing the risks of potential explosions and injuries; it is crucial for all industries with hazardous materials present.

Importance of ATEX Rating: Safeguarding Workplace Safety

Understanding ATEX rating is crucial in ensuring a hazardous-free workplace.

Employers must prioritize safety compliance and adhere to safety regulations for using intrinsically safe products and equipment.

The importance of ATEX rating cannot be overstated in ensuring workplace safety. It plays a vital role in the following:

1 – Compliance

ATEX rating ensures adherence to safety regulations by using intrinsically safe products, such as safety cameras, fans, lighting, and mobile devices, to prevent explosions.

2 – Risk Minimization

Using ATEX-rated equipment significantly reduces the risk of accidents and harm to personnel and property in potentially explosive atmospheres.

3 – Enhanced Standards

ATEX Rating raises safety standards, demonstrating a commitment to providing a safe work environment and fostering a safety culture.

4 – Education

Proper training in ATEX regulations and the use of compliant equipment empowers employees to participate in safety compliance efforts actively.

Overall, the significance of ATEX rating cannot be overstated when it comes to fostering a safe and hazard-free work environment.

Showcasing Exceptional ATEX Rated Products: Explore Safety Solutions by Intrinsically Safe Store

Intrinsically Safe Store offers an extensive array of exceptional ATEX-rated products, including customizable designs, to elevate workplace safety.

With a solid understanding of ATEX rating basics, now is the perfect opportunity to dive deeper and discover how our products can effectively meet your unique safety requirements.

“This LED headlight is very bright at 14,000 lumens. Very efficient and features really strong support. Designed to meet the highest engineering standards to keep you going in the dark.” — Offshore RigMan88, Verified Buyer

Let us demonstrate how we can assist you in achieving your safety goals and creating a tailored, hazard-free environment.

Revolutionizing Workplace Protection: Get Acquainted With ATEX Zone 1 and 2 Intrinsically Safe Cases by Intrinsically Safe Store

1 – Atexxo Intrinsically Safe iPhone 11 Zone 1

Designed specifically for use in Zone 1 hazardous environments, the Atexxo Intrinsically Safe iPhone 11 Zone 1 is certified by ATEX and IECEx.

Its sophisticated design and durable shell provide the utmost protection while preserving all aspects of the original product.

At Intrinsically Safe Store, we can assist you in selecting the right intrinsically safe products that meet the ATEX Zone 1 requirements, ensuring the safety of your employees and devices in hazardous areas.

“Don’t think twice about getting this intrinsically safe case to fully protect your iPad mini 5 in Zone 1 areas. It offers the most complete protection to your device, whether you are working at night or during day time.” — Offshore RigMan88, Verified Buyer

2 – Intrinsically Safe iPhone X Case

Intrinsically Safe iPhone X Case ATEX Zone 2 offers excellent protection for your iPhone in ATEX Zone 2 areas, guarding it against water, dirt, and dust particles.

With its ultra-rugged yet lightweight design, the intrinsically safe iPhone X case features an anti-slip and anti-scratch front and back cover, precise access holes, and impact dispersion technology.

At Intrinsically Safe Store, we can help you choose the appropriate intrinsically safe product for your iPhone X, providing peace of mind and safeguarding your device in ATEX Zone 2 locations.

ATEX Rating: Building a Hazard-Free Workplace for Enhanced Safety

A deep understanding of ATEX rating is essential for establishing a hazard-free workplace.

Employing intrinsically safe products that adhere to regulations is vital to ensure the safety of employees and avoid costly penalties.

Investing in ATEX-rated equipment becomes imperative for employers aiming to cultivate a safe and compliant work environment.

Through the knowledge gained from this basic guide, you can now make informed decisions on the best hazardous area ATEX-rated equipment suitable for your workplace.

Safety cameras, fans, lighting, and mobile devices significantly enhance workplace safety. By accurately categorizing and zoning hazardous areas, the risk of explosions can be minimized, ensuring secure working conditions for all.

However, the journey of education in this industry continues.

As technology advances and we learn more about the industry, advanced safety equipment emerges. That is why we provide a wealth of information on our website, as this industry constantly evolves.

Explore our ATEX certification archives for more insightful blogs that delve deeper into this topic and keep you up to date with the latest advancements in ATEX-rated workplace safety equipment.

The table below showcases some of our ATEX-certified equipment.

|

|

|

“It’s so bright and intrinsically safe, it’s perfect for dangerous environments.” — Archeal, Verified Buyer