As the manufacturing industry continues to evolve, the need for effective and efficient safety measures has never been more critical. One such measure is the implementation of Intrinsically Safe (IS) barriers. This article, brought to you by the Intrinsically Safe Store, will delve into the cost-benefit analysis of implementing IS barriers in manufacturing. We invite you to visit our website to learn more about our range of intrinsically safe products and services.

Understanding IS Barriers

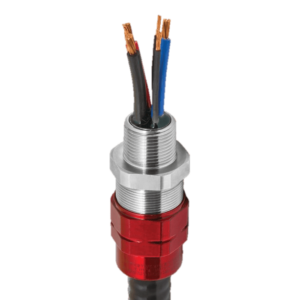

IS barriers are safety devices designed to limit the energy available for ignition in hazardous areas. They prevent sparks or high temperatures that could ignite flammable gases, dust, or vapors. These barriers are essential in industries such as oil and gas, chemical, pharmaceutical, and food processing, where explosive atmospheres may exist.

Costs of Implementing IS Barriers

Implementing IS barriers in a manufacturing environment involves several costs. These include:

- Initial purchase cost of the IS barriers

- Installation costs

- Maintenance and inspection costs

- Training costs for staff

While these costs can be substantial, it’s important to consider them as an investment in safety and efficiency.

Benefits of Implementing IS Barriers

The benefits of implementing IS barriers in manufacturing are numerous and can significantly outweigh the costs. These benefits include:

- Increased safety: IS barriers significantly reduce the risk of explosions, protecting both personnel and equipment.

- Reduced downtime: By preventing accidents, IS barriers can help avoid costly production stoppages.

- Compliance with regulations: Many industries are required by law to implement safety measures like IS barriers.

- Lower insurance premiums: Implementing safety measures can often lead to lower insurance costs.

Case Study: The Impact of IS Barriers in Manufacturing

A study conducted by the Aberdeen Group found that companies with superior safety practices, including the use of IS barriers, experienced a 12% higher profit margin than companies with average safety practices. This is a clear indication of the financial benefits that can be derived from investing in safety measures like IS barriers.

While the initial costs of implementing Intrinsically Safe barriers in manufacturing can be high, the long-term benefits in terms of safety, efficiency, and compliance make it a worthwhile investment. The use of IS barriers can significantly reduce the risk of accidents, protect valuable equipment, and ensure compliance with industry regulations. Furthermore, companies that prioritize safety measures like Intrinsically Safe barriers often see financial benefits in the form of higher profit margins and lower insurance premiums.

At the Intrinsically Safe Store, we understand the importance of safety in the manufacturing industry. We offer a wide range of intrinsically safe products and services designed to help you create a safer and more efficient work environment. Contact us today to learn more about how we can help you implement IS barriers in your manufacturing operations.